About Our Footstools

How we make our footstools and ottomans

Every piece of furniture is uniquely designed and is made to order to customers' specifications using a combination of the very best traditional and semi traditional methods and materials. We operate a non-foam policy for aesthetic and environmental reasons.

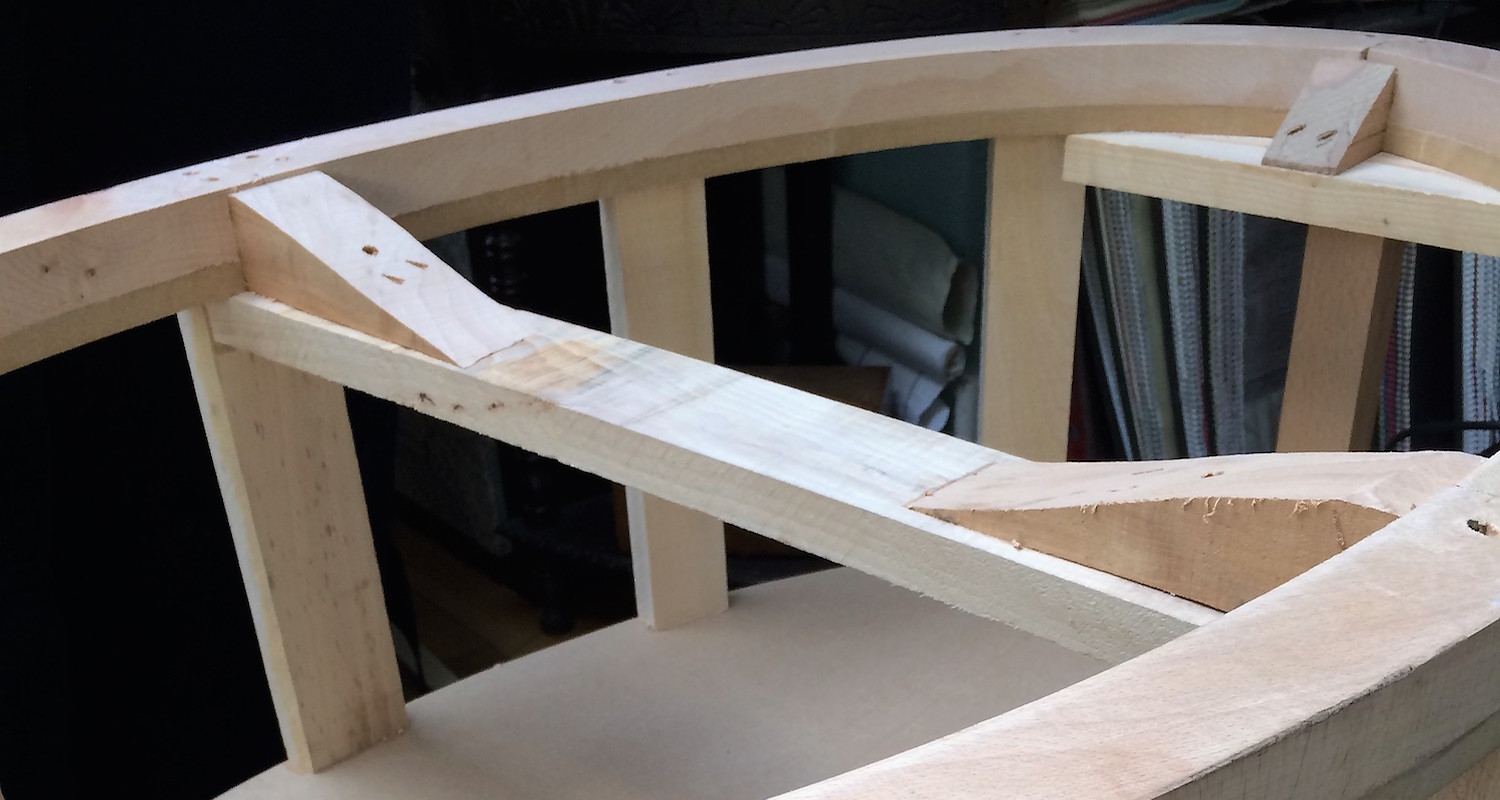

Our framemakers specialise in nothing but chair and stool frames, so their experience and workmanship is second to none. Classic European beech is the framemakers' choice and is the most sought after hardwood used in furniture worldwide because of its enduring and aesthetic properties. Each footstool frame is made to order as a single piece, based on size and customer's choice of legs. All legs are individually turned by the frame-makers in order to be proportionate in width and depth to the size of the stool. The stool frames are not made of component parts, they are designed as one. We do not simply screw in mass produced legs. Our frames are guaranteed for 10 years.

We apply several coats of shellac French polish to the legs after staining and we then finish by buffing with wax. This is far more labour intensive than factory sprayed lacquered legs, but we believe this produces superior results with the beautiful wood grain enhanced.

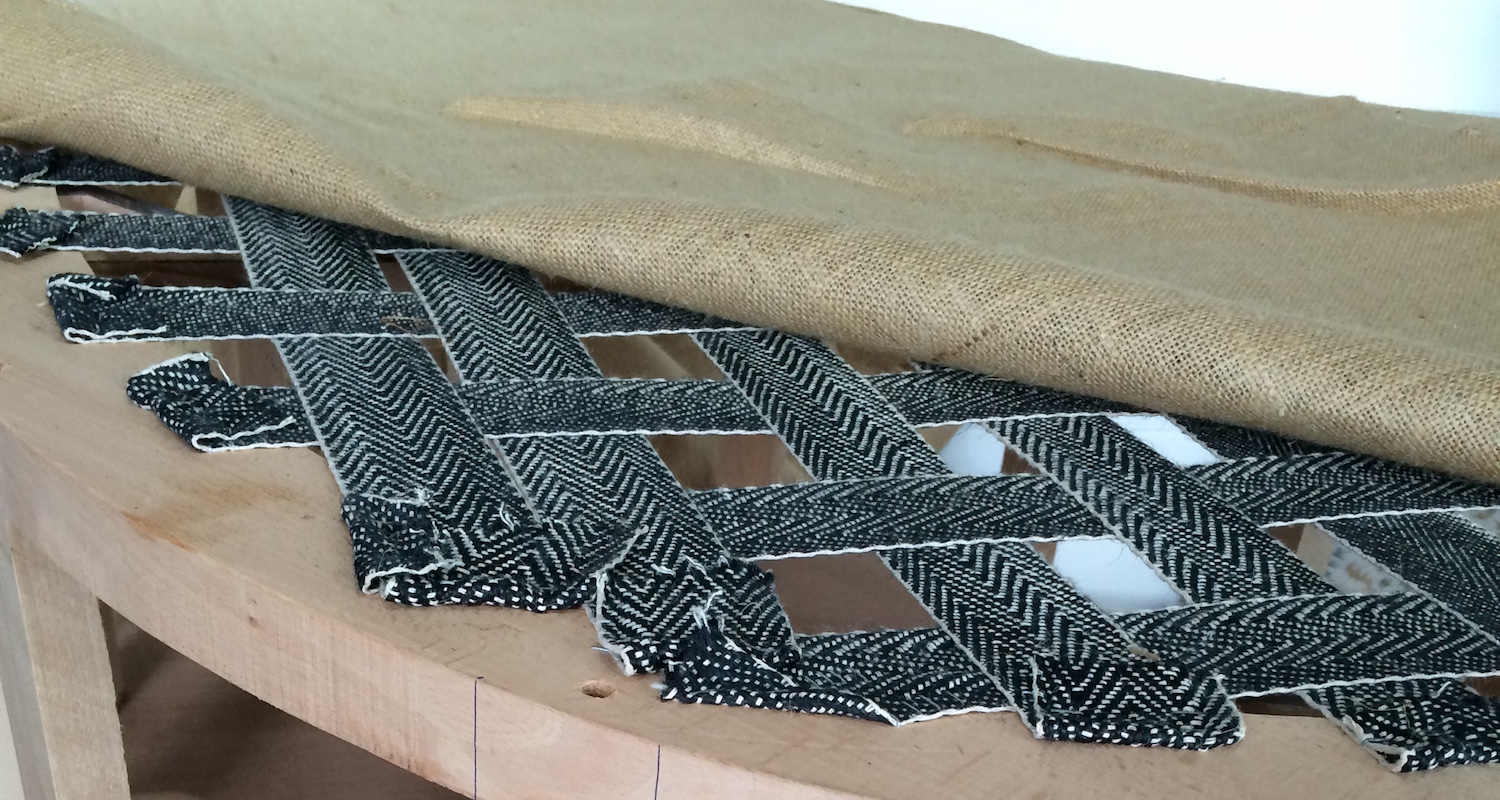

Black and white twill webbing is used, which is made of flax, and we use traditional and natural materials for stuffing - jute hessian, woolen felt, cotton linterfelt, fibre/hair pads, feather...(we do not use foam). By using natural fibres and low environmental impact materials to upholster durable solid frames from renewable sources, The Bespoke Footstool Company seeks to create pieces which will stand the test of time, while producing limited, and recyclable organic waste.

In order for furniture to pass the Furniture and Furnishings Fire Regulations 1988, a barrier cloth must be used under all non compliant fabric. Although fabrics can be "fire-retarded" and barrier cloths remove the need for fabrics to be chemically treated. We use a wool mix variety of barier cloth which has less environmental impact.

The footstool or ottoman is then finished with black cotton bottoming cloth which is secured with traditional fine tacks to the underside of all pieces.

Our commitment to fine British craftsmanship is reflected in the quality of construction and attention to detail.

About me

I set up The Bespoke Footstool Company out of demand for bespoke footstools through my bespoke chair business. I began to receive a steady stream of commissions, and so it was an obvious decision for me, as this is where my passions lie and I love making them. All of our footstools are designed by me, and created by hand and made entirely by British craftsmen.

Why Choose Us?

Design

Quality

Customer Service

Website by Greenleaf. All rights reserved.